Creative Decisions and Design Machine

A two month group project with the end goal of creating a successful and reliable machine to compete in Georgia Tech's ME 2110 Robotics Competition.

To find out more about the competition assignment, rules, and guidelines, click here.

Project Objective:

The objective of the Robo Incredible machine is to consistently and durably score 60points by collecting all 6 pillows that border the zone, and collecting all 4 T’s from Tech Tower while removing the F from the zone. We had to design within the strict project and competition guidelines including material, size, cost, timing, and much more.

Our "Robo-Incredible" machine won us 11th place in the competition out of 64 competing teams. We could not be more proud to have made it to the top "Sweet Sixteen!"

This class was probably the most valuable experience of my career at Georgia Tech. It had the time commitment of a part-time job and was worth every minute of it. Here's a list of some of the biggest and most important skills I took away from this project and class:

Teamwork teamwork teamwork

Long term time management

Technical writing

Presenting and Pitching

Problem solving

Mechatronics

Flexibility and adaptability

Product design planning

To the right, you can check out a video made by the course instructor (I have no rights). I think it does a great job in summing up the course in all of its glory!

The Take Away:

Final Renderings:

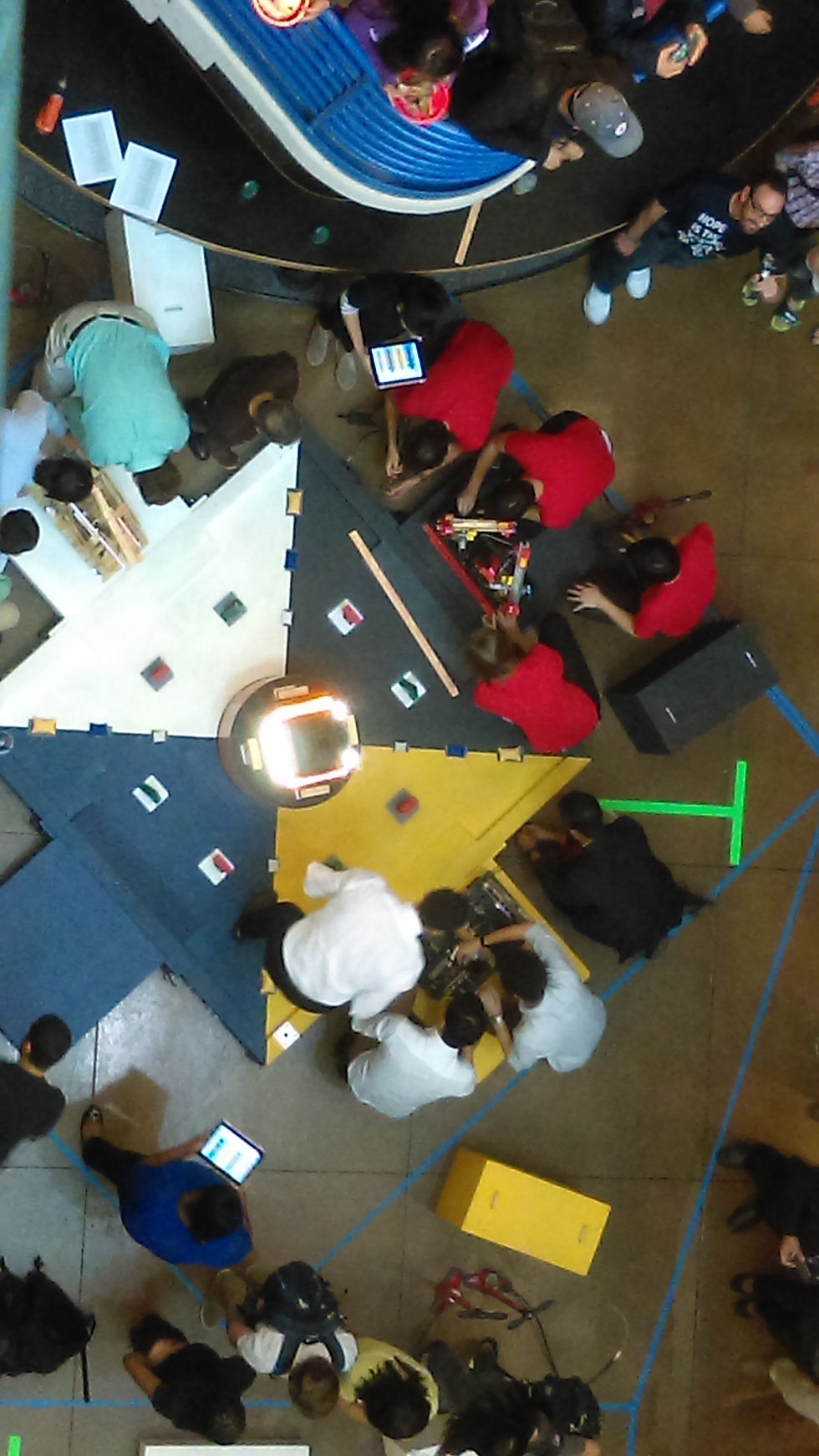

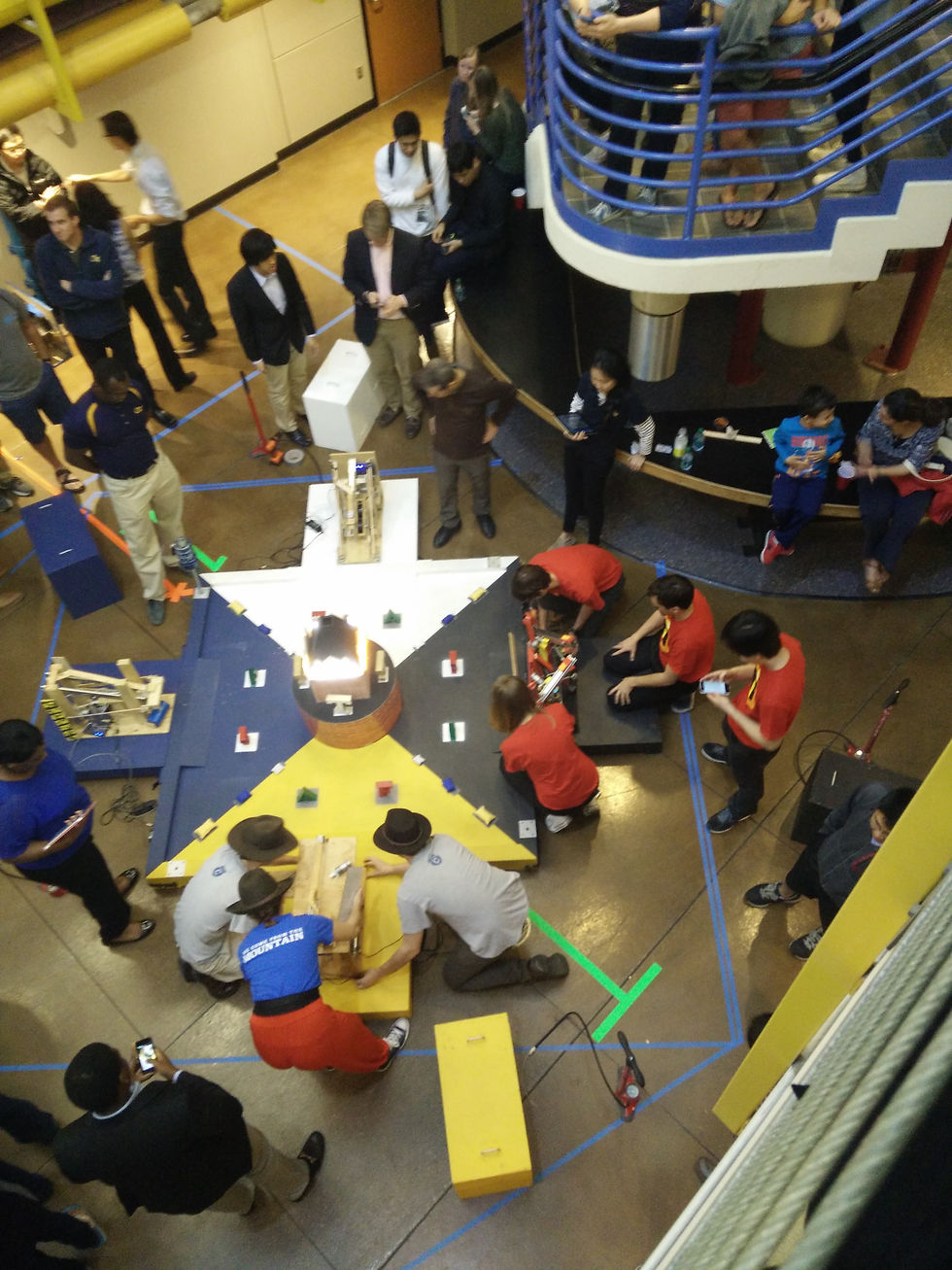

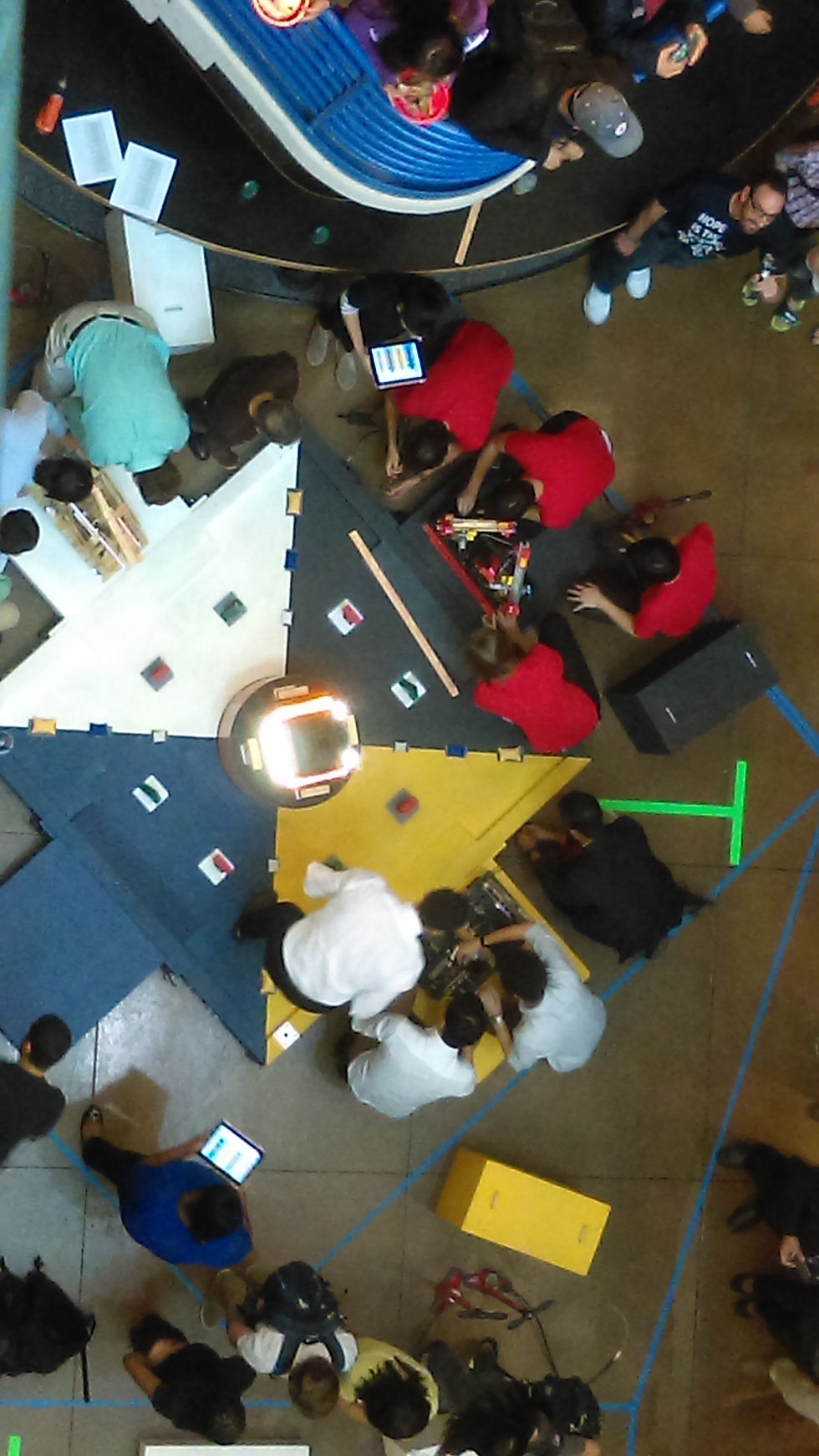

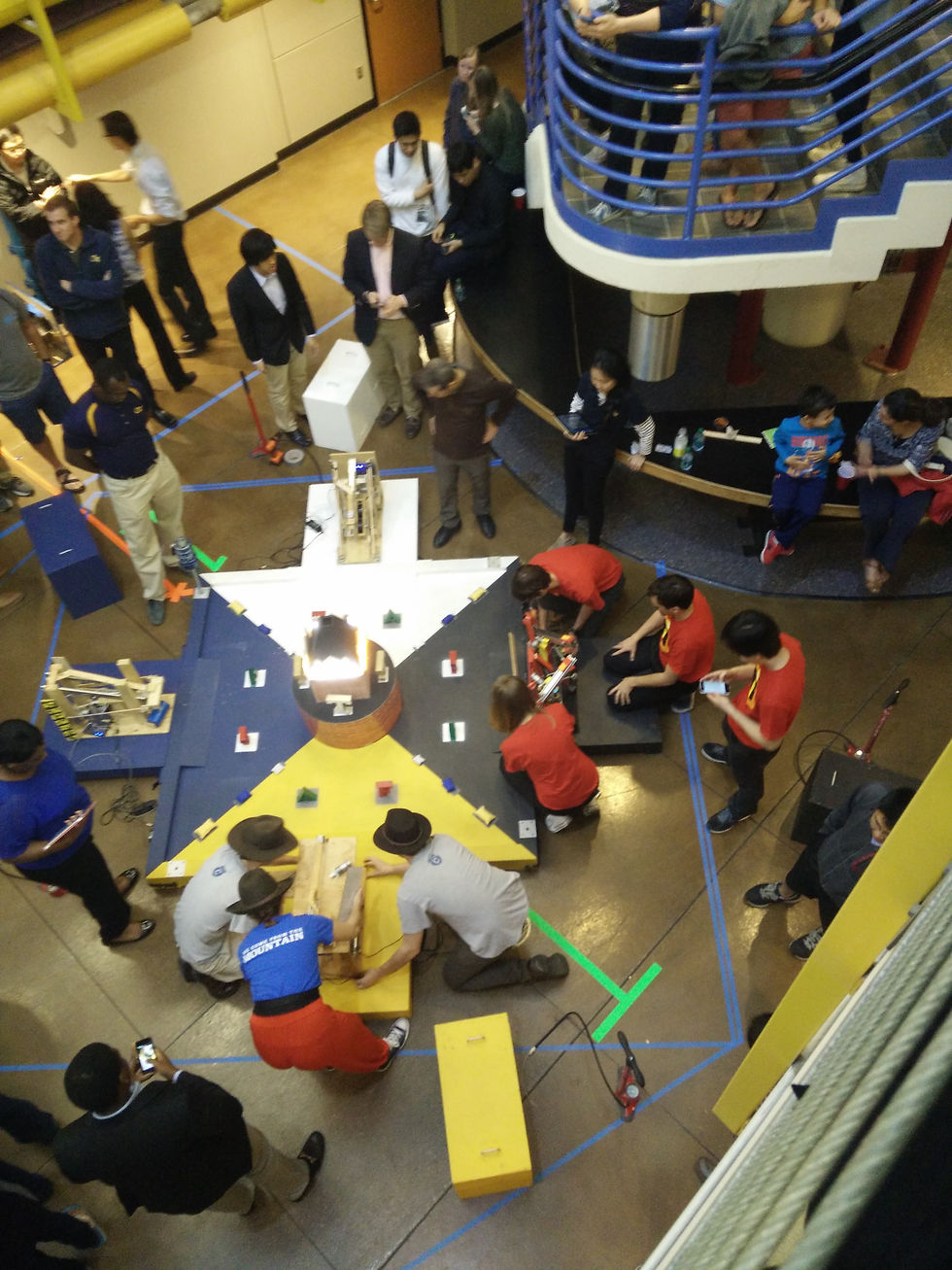

The Expo and Competition:

The Expo was a pre-competition judging period where we had the opportunity to show several official judges why our machine had the most innovative and intuitive design through a brief elevator pitch. We then moved on to the exciting, stressful, nail-biting competition. This consisted of many 2 minute rounds of rapid fire contraptions triggering, followed by hustling the machine into the back room to make quick fixes and reset our mechanisms. I'd be bluffing if I said it all went perfectly - things broke, duct-tape was involved, we had some challenges, but that was the fun of it!

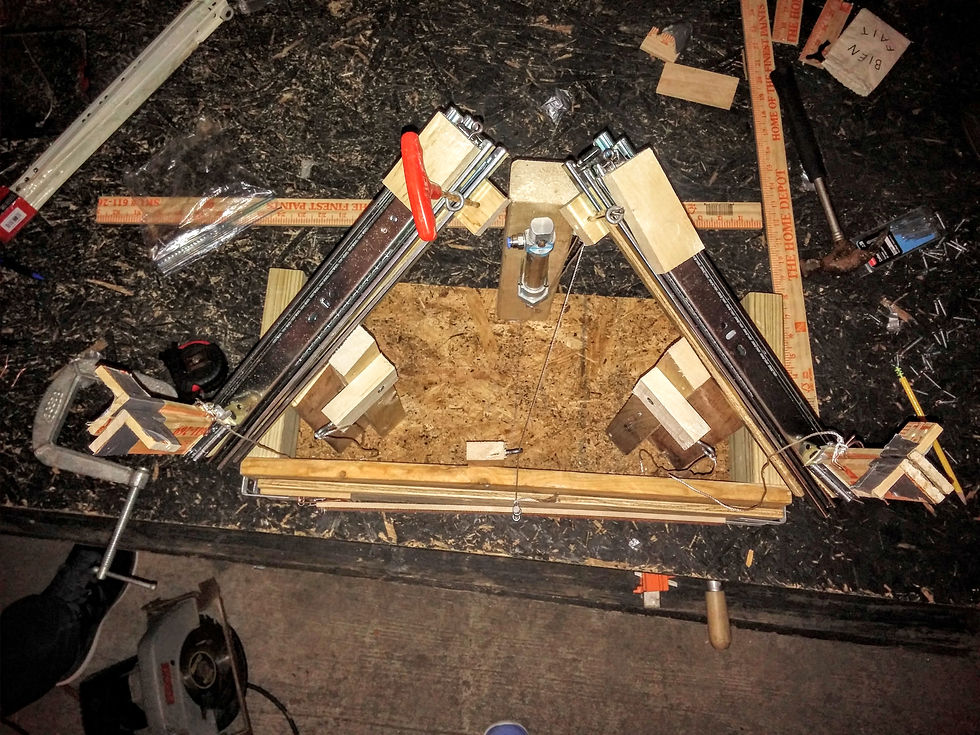

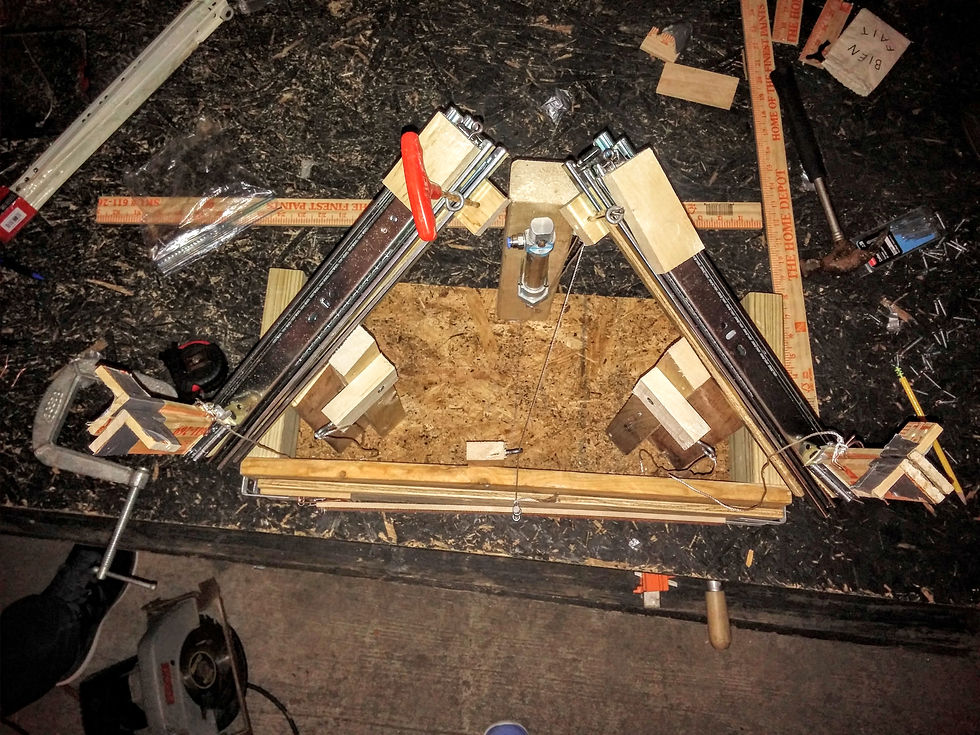

We began designing our machine by utilizing several design tools that were a part of the course. These included a House of Quality, function tree, solution matrix, time management tools, as well as others. If you would like to see any of these tools, I would be happy to provide them for you! We constructed the machine ourselves using shop power tools as well as machining tools available to us. We added and programmed the mechatronics components throughout to complete the mechanism functions. The team went through several implementation phases with more testing than you could imagine. To the right, you can check out some mid-build photos taken after a long night of building and testing.

The Process

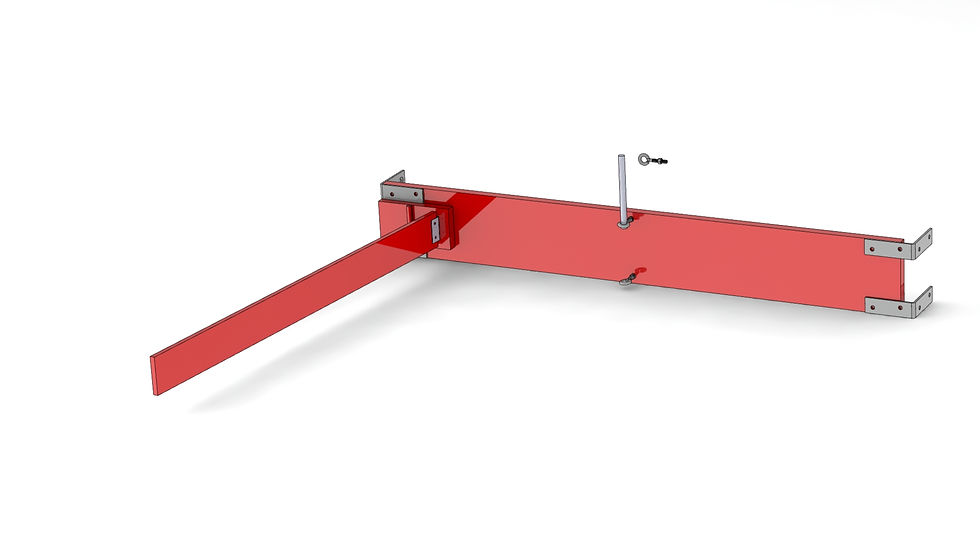

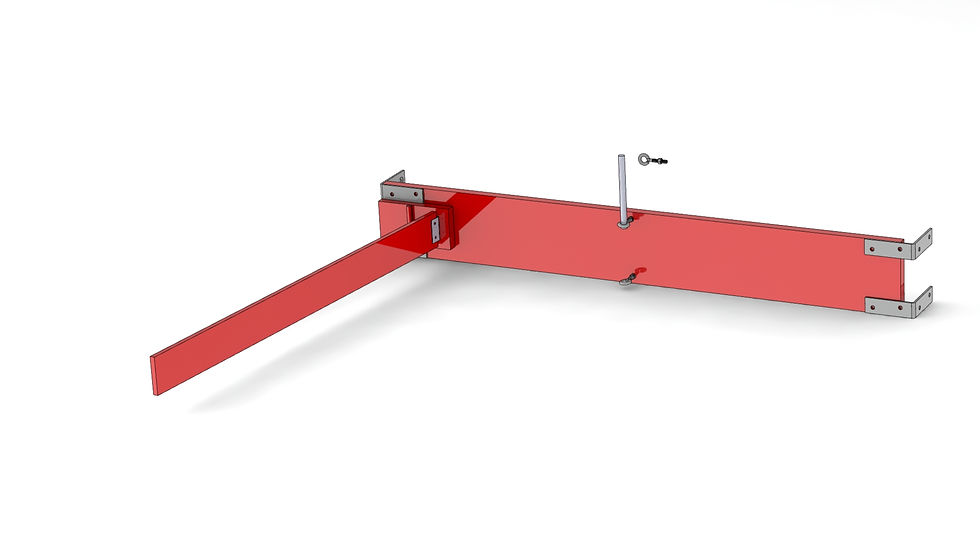

The Final Renderings:

Throughout the build, we utilized SolidWorks to model our machine to imagine how the different components would fit and work together. I was put in charge of these CAD models and created several iterations before we arrived at the renderings you see here. These were intended to showcase the machine and all of its mechanisms individually for our final paper and presentation. You can check out my team's final video presentation here! In addition, if you have even more curiosity about this project, I would be happy to provide our final written report.